NASA has conducted the first hot fire of a new RS-25 test series, beginning the final round of certification testing ahead of production of an updated set of engines for the SLS (Space Launch System) rocket.

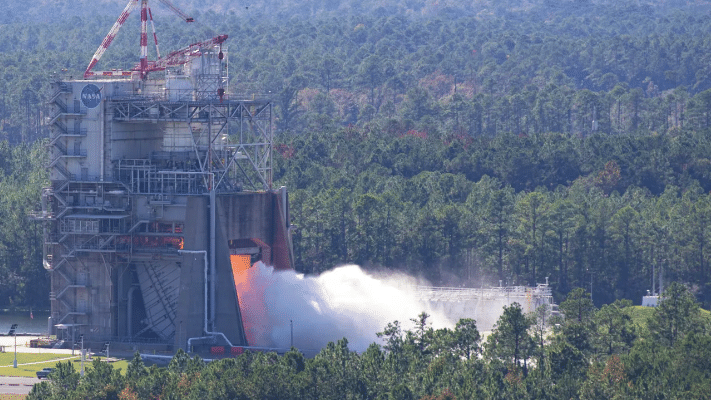

Operators fired the RS-25 engine for more than nine minutes, longer than the 500 seconds engines must fire during an actual mission, on the Fred Haise Test Stand at NASA’s Stennis Space Center near Bay St. Louis.

The engine was fired up to the 111 percent power level needed during an SLS launch. The hot fire marked the first in a series of 12 tests scheduled to stretch into 2024.

The tests are a key step for lead SLS engines contractor Aerojet Rocketdyne, an L3Harris Technologies company, to produce engines that will help power the SLS rocket, beginning with Artemis V.

The test series will collect data on the performance of several new key engine components, including a nozzle, hydraulic actuators, flex ducts, and turbopumps. The components match the design features of those used during the initial certification test series completed at the south Mississippi site in June.

Aerojet Rocketdyne is using advanced manufacturing techniques, such as 3D printing, to reduce the cost and time needed to build the new engines. Four RS-25 engines help power SLS at launch, including on its Artemis missions to the moon.

Through Artemis, NASA is returning humans, including the first woman and the first person of color, to the moon to explore the lunar surface and prepare for flights to Mars. SLS is the only rocket capable of sending the agency’s Orion spacecraft, astronauts, and supplies to the moon in a single mission.